FIVA / ELFI / HPS for MAN engine

Fuel Injection Valve Activation :

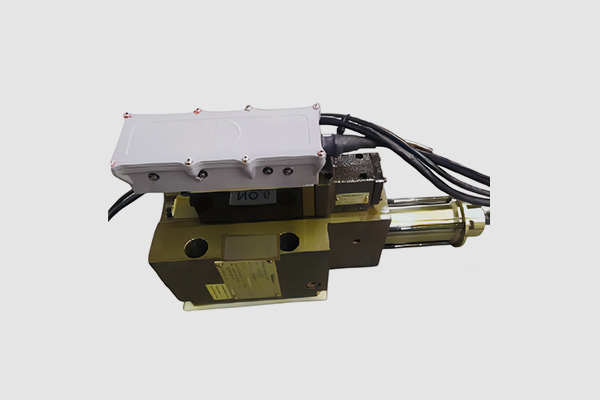

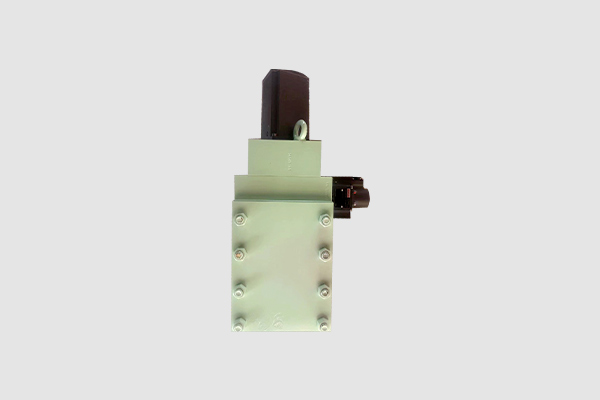

FIVA

Work Scope

FIVA-MBD

FIVA- NABTESCO

FIVA-REXROTH

Work Scope:

Test Bench:

| Detail Data of Calibration and Function Test | |||||

| Serial No | #2 | Type | STW 0175-14/ | ||

| New pilot valve | None | New position sensor | None | ||

| Overhaul to check the electro-mechanical convertor and coil | Ok | ||||

| Control spool and bush is examined under a microscope | Ok | ||||

| Proportionalvalve on bench to testing | Ok | ||||

| Oil temperature | Reference value | 42 ºC±1 ºC | Oil pressure | Reference value | 250±3bar |

| Measured value | 42.04ºC | Measured value | 250.16bar | ||

| Flow rate | Reference value | 15±0.2L/min | Zero adjustment | Reference value | 12.20±0.02mA |

| Measured value | 15.08 L/min | Measured value | 12.20 mA | ||

| FIVA valve is function test, calibrate and internal leakage measurement | 6.79 L/min | ||||

| Output signal from inductive sensor in both extreme positions | 5.30 mA / 19.16 mA | ||||

| Output signal of default position (on loss of pilot valve command signal) | 5.30 mA | ||||

| Output signal stamped on the name plate (original) | 12.24 mA | ||||

| Output signal from new inductive sensor when calibration rod is mounted | 12.20 mA | ||||

| Result: | Overhaul, Maintenance, Calibration, FIVA is in working condition, Function Testing is acceptable; | ||||

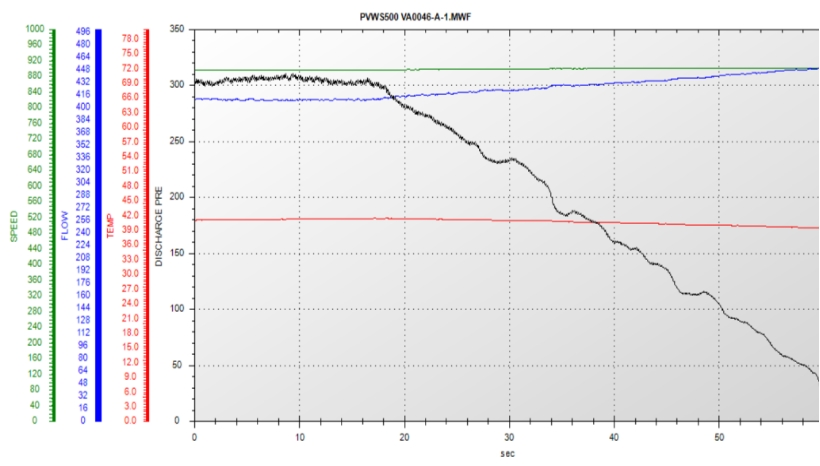

| HPS Pump on test bench to simulated engine condition | ||||||||||

| Rotation | □ R | ☑L | Oil cleanliness grade NAS | NAS 7 | ||||||

| Test Speed | 900 RPM | Max.displacement | 500 cm3 | |||||||

| Temperature | 34℃ | Test flow rate | 450 L/min | |||||||

| Oil Pressure / (bar) | 0 (25) | 100 | 150 | 200 | 250 | 300 | 350 | |||

| Flow / L/min) | 450 | 441 | 434 | 426 | 416 | 404 | ||||

| Leakage %,/100bar | 2.00% | 2.37% | 2.67% | 3.02% | 3.41% | |||||

|

||||||||||